SCM Ref high temperature heat pump

SCM Ref belongs to the OEM division of Beijer Ref and is specialized in developing units with a specialization in natural refrigerants. In order to be able to meet the increasing demand for high temperature heat pumps, SCM Ref developed a unique product line consisting of four types.

The heatpumps are developed to work with NH3 as refrigerant, which is commonly recognized as one of the best refrigerants for heatpump application.

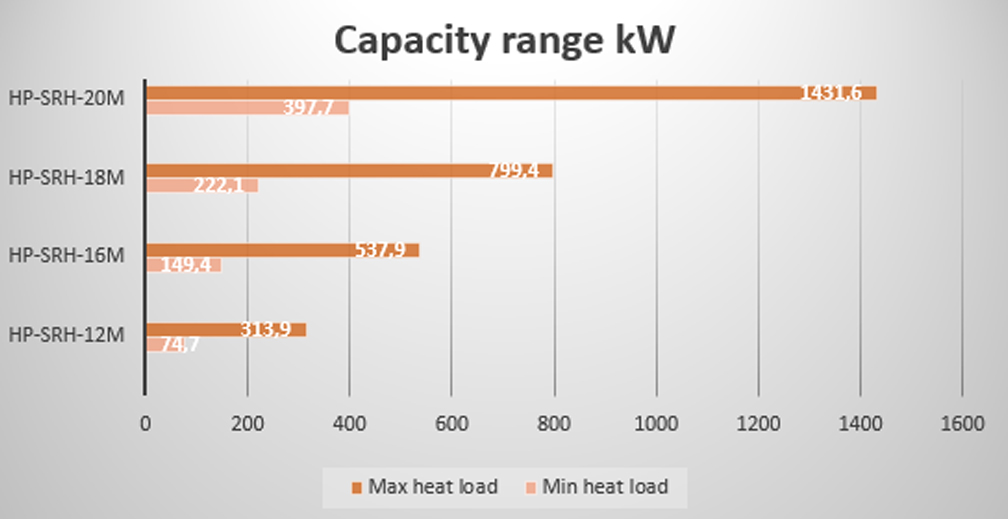

Starting with the smallest heatpump at a capacity of approximately 320 kW it goes all the way up to 1,4 MW. This is based on delivery water temperatures between +50 and +80 degrees. (90 degrees as an optional).

The configuration of the heat pump is unique and more reliable than the conventional cascade systems, which are commonly used to overcome such high-pressure ratios, because one stage compression application is less complex to set up.

With ground source inlet temperatures of approximately +12 degrees at the cold source and an outgoing hot water demand of +80 degrees normally two compressors are used working at different pressure stages to reach a satisfied energy profile.

By using a unique setup of heat exchangers in combination with a high pressure (63 bar) screw compressor, SCM Ref is able to comply to the Dutch EIA subsidy rules even when the equipment is designed for one stage compression mode.

It is made possible because of the use of dedicated heat pump software, that monitors the working envelop of the screw compressor, which is equipped with patented rotor profiles special developed for this heating applications.

This software running on a Siemens S7 PLC platform is easily accessible by TCP-IP protocol for remote monitoring by means of a laptop, PC and even on your smart phone it will pop up very easily. It works closely with a Danfoss frequency drive, which ensures the compressor and motor running smoothly over a wide capacity range. The requested and delivered energy amount is calculated and visualized clearly on trend graphs in color HMI.

There has also been a focus on low charge volume of the NH3 application by using plate heat exchangers and the unique controller software. The control algorithm of the software makes it possible to combine heat reclaim functions to only one heat exchanger. This eliminates the use of two extra heat exchangers in the heat reclaim loop.

This means the use of less components which contributes to an organized and user friendly heatpump. Maintenance and service friendly set-up of the equipment with using much fewer components makes it an easy-to-handle heat pump for the engineers who has to work on it.

Special attention is given to secure lubricating and temperature reliability of the oil loop.

Because of the high-pressure ratios and temperatures, the compressor is exposed to, there is a backup system to secure sufficient lubrication, also in case there is an unbalanced hydraulic system at the heating side of the building. This failsafe application also contributes to increase the energy efficiency by acting as a fine tune regulation as well.

The software will not only monitor the heat pump itself but will also take the external process variables into consideration. During start up there is a special ramp-up software mode that secures the way cold is extracted from the cold ground source, securing it is not exposed to an extreme cold extraction. (During start up the cold load will be much higher because of the lower water outlet temperatures at the hot side). In case pressure differences are not enough to secure sufficient lubrication over the compressor during this phase of ramping up an oil pump will be activated. The compressor is equipped with a Vi regulation, to overcome over and under compression during different working conditions, which ensures the optimal running conditions at all times.

With a robust screw compressor at the beating heart of the heat pump it is extremely reliable and service friendly. Maintenance for the engineers in the field is kept to a minimum and the equipment is very robust and designed for failsafe operation. On the hot water side, the implemented heat exchangers have a very high K value. The semi welded application of those heat exchangers means that they are easy to clean in case of the presence of contaminations in the water.

The screw compressor application is less vulnerable for unbalanced situations and the service intervals are much more competitive compared to the applications where for example piston compressors are used.

The unique and broad SCM Ref field experience features, gathered in the software controls and combined with unique highly efficient components makes this heatpump one of the greenest solutions SCM Ref has to offer to the market.