SCM REF S-Line chiller

SCM Ref, which belongs to the OEM division of Beijer Ref group, is specialized in developing units using natural refrigerants. In order to meet the increasing demand for ultra low charge chillers, SCM Ref developed an unique S line NH3 chiller in addition to its standard NH3 line for AC and Process application.

So, what makes S line chiller Smart?

First and foremost, it uses NH3, a type of natural refrigerant with zero global warming or ozone depletion potentials. It is the greenest refrigerant available to refrigeration and AC market. When you choose NH3, you also choose to protect earth. S line chillers are all equipped with high efficiency oil return system and 3-stage oil separator. In our test run, they are approved to leave no trace of oil left behind in the heat exchangers.

It also has unique low filling rate. Across S line chillers, the NH3 filling rate is below 10kg. In many countries, the safety regulation on NH3 will be loosened significantly because of that. It makes working with a NH3 cooling plant much easier. S line chiller can achieve such low filling rate by using water- cooled semi-welded plate heat exchangers for NH3 condensing and oil cooling. This type of heat exchangers have 2 advantages: smaller delta T approach and easy maintenance in case of water-side pollution. We also offer V-shape dry coolers in the package. They are engineered specially for S line application. They have very small footprint, independent dry-cooler controller, integrated humidity and temperature sensor, hydrophobic fins and chamber. In practice, they have much higher efficiency and are adaptable to very high ambient temperature, which will be mentioned later.

S line chillers have unique compressors in the heart. These innovative twin rotors screw compressors are semi-hermetically sealed, which eliminates leakage from shaft seal completely. Inside, they are equipped with high efficiency PM motors, which are also resistant to NH3 corrosion. These compressors have better efficiency also because of the rotor profile designed for refrigeration and patented to these compressors exclusively.

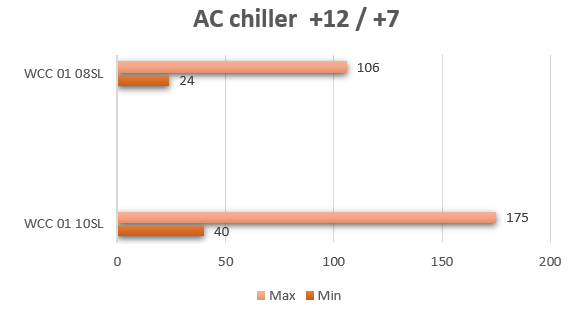

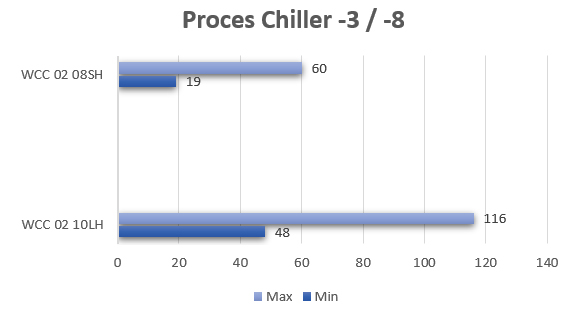

We developed and tested a smartly designed control algorithm based on liquid gas fraction. It allows S line chillers to run on a much higher efficiency, about 20% more than conventional NH3 DX chillers. For owners and investors, this means a reduction in investment and shorter payback cycle. We also implemented algorithms to work with the capacity control of compressors to allow a wide capacity range. More can be seen in the capacity chart in attachment.

Another benefit of S line’s smart controller program is that, it enables master-slave configuration out of box. In the events like production expansion, up to 2 additional S line chillers can be coupled to the existing “master” chiller. Installers can configure it easily on the touchscreen. So the end user can have tripled cooling capacity within a very short period of time. It is also possible to combine chillers with different capacity to find the best fit for your peak and bottom capacity. Master-slave configuration also brings high redundancy, which is specially important to many industrial applications.

S line has AC and Process models. AC line has water/brine outlet temperature settable between +4°C and +10°C, and for process models it is between -11°C and -2°C. (for set point outside of the given range, please consult SCM REF BV) Additionally, set point shift function is built-in. It enables a chiller to switch to a different set point using external input signal. In this way, operation can be made more flexible and economical.

Facing increasing abnormally hot summer days, which are mostly like caused by global warming, S line is designed for extremely high ambient temperature, up to 45°C ambient temperature. S line chiller will keep your facility cool during the days when you need it most. Such high tolerance to ambient is possible because the adiabatic chamber allows dry coolers to cope with high temperature that is previously unthinkable. It is also because the design pressure for S line is 28/20 bars—higher design pressure allows higher condensation pressure and brings more safety. Last but not least is the unique controller algorithm constantly monitoring and optimizing the performance in the background.

S line has industrial grade electrical cabinet housing inside a Siemens S7 PLC, colour touchscreen together with Danfoss frequency drive to achieve optimum partial load efficiency. The unique chiller controller software developed by SCM REF is installed in every PLC. Remote access is enabled by a smart router, which can be fitted with cellular sim card, ethernet port or wifi network adapter. Installers and end users can access the operation data on their computers or smartphones thru free software. There is no need to call extensive IT support for tasks like setting up VPN connection. Everything is ready to use out of box.

The casings has very small footprint due to the compact chiller design. Absorption dampers are mounted by default. Its size makes it easily movable by forklifts. To make it more convenient for installers, the water/brine pipes can be connected from either side of the chiller. There are also options designed to meet various demand: one can have indoor or outdoor casing, with or without sound absorption layers. To comply with international rules, a preset gas detector is installed as well as ATEX fans for NH3 extraction and temperature control inside the casing. Additional standalone alarm panel can be integrated into casing or installed remotely.

Lastly, these chillers are built in SCM REF workshop in Netherlands according to very high standards. The complete units are built with fully welded stainless steel pipes even for the thin signal lines. This together with semi-hermetic compressors will reduce the risk of leakage and need for maintenance greatly. The framework is protected with industrial grade C3 layer against metal corrosion. The units are assembled by experienced engineers, prechecked in workshop, tested with X-ray, delivered with PED certificate.

S line blurs the line between commercial and industrial chillers. They have the performance, stability and high quality components like industrial products. Meanwhile, their compact look and flexible capacity range is akin to their commercial siblings. We are confident S line chillers will provide the cooling solution the industries need while protecting our environment for many years to come.